Mukuyerwa kwekumanikidza, unogona kuona kuti mibairo yekuyera haingoratidzi shanduko mukudzvanywa kwekuisa kana kuenderana zvizere kana dzvinyiriro ichidzokera kune yayo yekutanga. Semuenzaniso, kana uchishandisa chikero chekugezera kuyera uremu, sensor yechiyero inoda nguva yekunyatsonzwisisa uye kudzikamisa kuverenga kwehuremu hwako. Thenguva yekupinduraye sensor inotungamira kune yekutanga data kuchinja. Kana iyo sensor ichinge yagadzirisa mutoro uye ichipedzisa kugadzirisa data, kuverenga kunoratidza mhedzisiro yakagadzikana.Uku hakusi kukanganisa kwesensor asi hunhu hwakajairwa hwemazhinji emagetsi ekuyera maturusi, kunyanya kana ichisanganisira chaiyo-nguva yekugadzirisa data uye yakatsiga-mamiriro kubudirira. Ichi chiitiko chinogona kunzi se sensor hysteresis.

Chii chinonzi hysteresis mukumanikidza sensors?

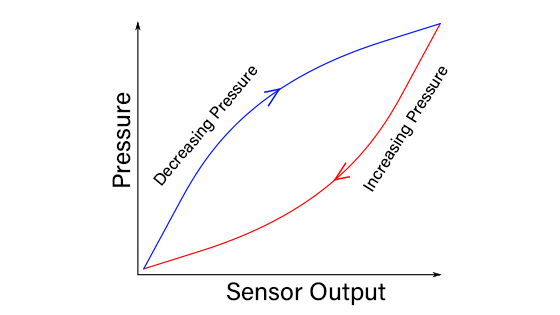

Sensorhysteresiskazhinji inotaridza kana paine shanduko yekupinda (senge tembiricha kana kudzvanywa), uye chiratidzo chekubuda hachingoteedzere shanduko yekupinda, kana iyo inopinza ichidzokera kune yayo yekutanga, siginecha inobuda haidzokeri kumamiriro ayo ekutanga. . Ichi chiitiko chinogona kuoneka pane sensor's hunhu curve, pane yakarembera-yakaita loop curve pakati pekupinda nekubuda, pane mutsara wakatwasuka. Kunyanya, kana iwe ukatanga kuwedzera iyo yekupinda kubva kune imwe chaiyo kukosha, iyo sensor inobuda ichawedzerawo zvinoenderana. Nekudaro, iyo yekuisa painotanga kudzikira ichidzokera kune yekutanga poindi, iwe uchaona kuti iyo inobuda kukosha yakakwira kupfuura yepakutanga kuburitsa kukosha panguva yekudzikisa maitiro, kugadzira loop kana.hysteresis loop. Izvi zvinoratidza kuti panguva yekuwedzera uye kuderera kwemaitiro, kukosha kwakafanana kwekuisa kunoenderana nemhando mbiri dzakasiyana dzekubuda, inova intuitive kuratidzwa kwe hysteresis.

Iyo dhizaini inoratidza hukama pakati pekubuda uye kuisirwa kudzvanywa mune yekumanikidza sensor panguva yekumanikidza application process, inomiririrwa muchimiro che hysteresis curve. Iyo yakatwasuka axis inomiririra sensor kubuda, uye vertical axis inomiririra kudzvanywa. Iyo tsvuku tsvuku inomiririra nzira iyo iyo sensor kubuda kunowedzera zvishoma nezvishoma kuwedzera kudzvinyirira, kuratidza nzira yekupindura kubva pasi kusvika kune yakakwirira. Iyo yebhuruu curve inoratidza kuti sezvo kudzvanywa kwakaiswa kunotanga kudzikira, iyo sensor inobuda inodzikirawo, kubva pakakwirira kudzvinyirirwa ichidzokera pasi, ichiratidza maitiro e sensor panguva yekuburutswa kwekumanikidza. Nzvimbo iri pakati pema curves maviri, iyo hysteresis loop, inoratidza mutsauko mukubuda kwe sensor pane imwechete yekumanikidza nhanho panguva yekurodha uye kurodha, kazhinji inokonzerwa nehunhu hwemuviri uye chimiro chemukati che sensor material.

Zvikonzero zvePressure Hysteresis

Iyo hysteresis phenomenon inpressure sensorsinonyanya kupesvedzerwa nezvinhu zviviri zvikuru, izvo zvine hukama zvakanyanya neayo emuviri zvivakwa uye mashandisirwo ekushanda kwe sensor:

- Material's elastic hysteresis Chero chinhu chinozoenda kune imwe dhigirii ye elastic deformation kana ichiiswa kune ekunze masimba, mhinduro yakananga yezvinhu kune masimba akaiswa. Kana simba rekunze rabviswa, zvinhu zvinoedza kudzokera kumamiriro ayo epakutanga. Nekudaro, kudzoreredza uku hakuna kukwana nekuda kwekusafanana mukati memukati mechimiro chemukati uye kudiki kusingadzoreki shanduko mumukati meiyo microstructure panguva yekudzokororwa kurodha uye kurodha. Izvi zvinokonzeresa lag mune mechaniki maitiro ekubuda panguva yekuenderera kurodha uye kurodha maitiro, anozivikanwa seelastic hysteresis. Ichi chiitiko chinonyanya kuoneka mukushandiswa kwepressure sensors, sezvo masensa kazhinji anoda kuyera uye kupindura kudzvinyirirwa shanduko nenzira kwayo.

- Kupokana Mumichina yemagetsi sensor sensor, kunyanya iyo inosanganisira zvikamu zvinofamba, kukwesha hakudzivisike. Uku kukakavara kunogona kubva kune vanobatana mukati me sensor, senge inotsvedza yekuonana mapoinzi, mabhengi, nezvimwe. Kana iyo sensor inotakura kudzvanywa, idzi friction point dzinogona kutadzisa kufamba kwemahara kweiyo sensor yemukati mechanical zvimiro, zvichikonzera kunonoka pakati pemhinduro ye sensor uye pressure chaiyo. Kana kudzvinyirirwa kwacho kusunungurwa, masimba akafanana ekurwisana anogonawo kudzivirira zvivako zvemukati kuti zvimire pakarepo, nokudaro zvichiratidzawo hysteresis panguva yekudzikisa.

Izvi zvinhu zviviri pamwe chete zvinotungamira kune iyo hysteresis loop inocherechedzwa mumasensa panguva yekudzokororwa kurodha uye kuburitsa bvunzo, hunhu hunowanzo nyanya kunetseka mumashandisirwo apo kunyatso uye kudzokororwa kunodiwa zvakanyanya. Kuti uderedze kukanganiswa kweiyi hysteresis phenomenon, kunyatso dhizaini uye kusarudzwa kwezvinhu zve sensor kwakakosha, uye software algorithms inogona zvakare kudikanwa kutsiva iyi hysteresis mumashandisirwo.

Iyo hysteresis phenomenon inpressure sensorsinopesvedzerwa nezvakasiyana zvinhu zvine chekuita zvakanangana neiyo sensor yemuviri uye makemikari zvivakwa uye yayo inoshanda nharaunda.

Ndezvipi zvinhu zvinotungamira kune sensor hysteresis?

1. Material properties

- Elastic modulus: Iyo yezvinyorwa elastic modulus inotaridza dhigirii reiyo elastic deformation kana ichiiswa pasi pekumanikidza. Zvishandiso zvine yakakwira elastic modulus deform zvishoma, uye yavoelastic hysteresisinogona kunge yakaderera.

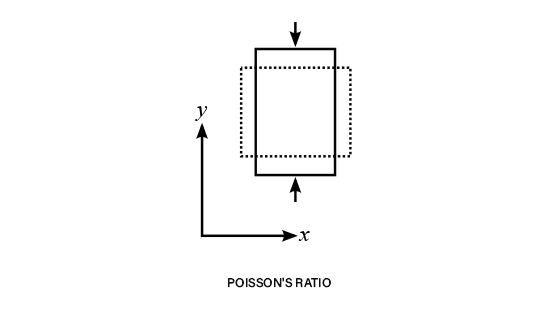

- Chiyero chePoisson: Chiyero chePoisson chinotsanangura chiyero che lateral contraction kune longitudinal elongation muchinhu kana chaiswa pasi pekumanikidza, izvo zvinokanganisawo maitiro echinhu panguva yekurodha nekuburitsa.

- Chimiro chemukati: Iyo microstructure yezvinyorwa, kusanganisira crystal chimiro, kukanganisa, uye inclusions, inokanganisa maitiro ayo emagetsi uye hysteresis maitiro.

2. Manufacturing process

- Machining precision: Iyo chaiyo ye sensor chikamu machining inobata zvakananga kuita kwayo. Zvikamu zvine hunyanzvi hwepamusoro zvinokwana zvirinani, kuderedza kukweshera uye kushushikana kunokonzerwa nekusakwana.

- Kukasharara kwepamusoro: Hunhu hwekurapa kwepamusoro, hwakadai sehukukutu hwepamusoro, hunokanganisa ukuru hwekukweshana, zvichikonzera kukurumidza kwekupindura kwe sensor uye hysteresis.

- Shanduko yetembiricha inokanganisa hunhu hwezvinhu, senge elastic modulus uye friction coefficient. Kupisa kwakanyanya kunowanzoita kuti zvinhu zvipfave, zvichidzikisa elastic modulus uye kuwedzera kukweshera, nekudaro kuwedzera hysteresis. Sezvineiwo, tembiricha yakaderera inogona kuita kuti zvinhu zviome uye zvakanyanya brittle, zvichikanganisa hysteresis nenzira dzakasiyana.

3. Tembiricha

- Shanduko yetembiricha inokanganisa hunhu hwezvinhu, senge elastic modulus uye friction coefficient. Kupisa kwakanyanya kunowanzoita kuti zvinhu zvipfave, zvichidzikisa elastic modulus uye kuwedzera kukweshera, nekudaro kuwedzera hysteresis. Sezvineiwo, tembiricha yakaderera inogona kuita kuti zvinhu zviome uye zvakanyanya brittle, zvichikanganisa hysteresis nenzira dzakasiyana.

Njodzi

Kuvapo kwe hysteresis mukatipressure sensorsinogona kukonzera zvikanganiso zvekuyera, kukanganisa kurongeka uye kuvimbika kwe sensor. Muzvishandiso zvinoda kuyerwa kwepamusoro-chaizvo, senge kurongeka kwemaindasitiri maitiro ekudzora uye yakakosha yekutarisisa michina yekurapa, hysteresis inogona kutungamirira kuzvikanganiso zvakakura zvekuyera uye kutokonzera kuti kuyerwa kwese kutadza. Naizvozvo, kunzwisisa uye kuderedza kukanganiswa kwe hysteresis chikamu chakakosha chekuona kushanda kwakanaka uye kwakaringana kwe.pressure sensors.

Mhinduro dzeHysteresis muPressure Sensors:

Kuve nechokwadi cheyakaderera inogoneka hysteresis mhedzisiro mukatipressure sensors, vagadziri vatora akati wandei akakosha matanho ekugonesa sensor performance:

- Kusarudzwa kwezvinhu: Sarudzo yezvishandiso inoita basa rekuita muhysteresis. Naizvozvo, vagadziri vanonyatso sarudza zvepakati zvinhu zvinoshandiswa mukuvaka sensor, senge diaphragms, zvisimbiso, uye kuzadza zvinwiwa, kuve nechokwadi chekuti vanoratidza kushoma hysteresis pasi pemamiriro akasiyana ekushanda.

- Dhizaini dhizaini: Nekuvandudza dhizaini dhizaini yemasensa, senge chimiro, saizi, uye ukobvu hwemadiaphragms, uye nekugadzirisa nzira dzekuisa chisimbiso, vagadziri vanogona kunyatso kudzikisa hysteresis inokonzerwa nekukwenya, static friction, uye deformation yezvinhu.

- Kurapa kwekuchembera: Ichangobva kugadzirwa sensors inogona kuratidza yakakosha yekutanga hysteresis. Kuburikidzakuchembera kurapwauye mapurogiramu chaiwo ekuedza, zvinhu zvinogona kukwidziridzwa kuti zvigadzikane uye zvigadzirise, nokudaro kuderedza iyi yekutanga hysteresis. Mufananidzo uri pasi apa unoratidzaXDB305zviri kuitikakuchembera kurapwa.

- Yakasimba kugadzirwa kwekutonga: Nekunyatso kudzora kushivirira uye mhando panguva yekugadzira maitiro, vagadziri vanovimbisa kuenderana kwese sensor yega yega uye kuderedza kukanganiswa kwekusiyana kwekugadzira pane hysteresis.

- Yepamberi calibration uye muripo: Vamwe vagadziri vanoshandisa advanced digital compensation tekinoroji uye akawanda-point calibration nzira kuti vanyatso kutevedzera uye kugadzirisa hysteresis mune zvinobuda sensor.

- Kuyedzwa kwekuita uye giredhi: ese ma sensors anoongororwa zvakadzama kuti aongorore maitiro avo ehysteresis. Zvichienderana nemhedzisiro yebvunzo, masensa anoiswa giredhi kuti ave nechokwadi chekuti zvigadzirwa chete zvinosangana yakatarwa hysteresis zviyero zvinoburitswa kumusika.

- Yekukurumidza kuyedza hupenyu: Kuti uone kugadzikana kwekuita kwema sensors mukati menguva yavo yaitarisirwa yehupenyu, vagadziri vanomhanyisa kuchembera uye bvunzo dzehupenyu pamasamples kuona kuti hysteresis inoramba iri mukati memiganhu inogamuchirwa.

Aya matanho akakwana anobatsira vagadziri kunyatso kudzora uye kuderedza iyo hysteresis phenomenon mukatipressure sensors, kuve nechokwadi chekuti sensors inosangana nehupamhi hwepamusoro uye kuvimbika zvinodiwa mumashandisirwo chaiwo.

Nguva yekutumira: Chivabvu-09-2024